Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

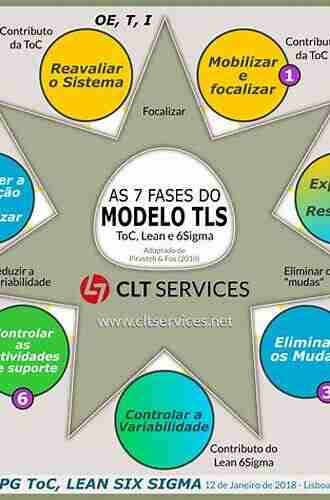

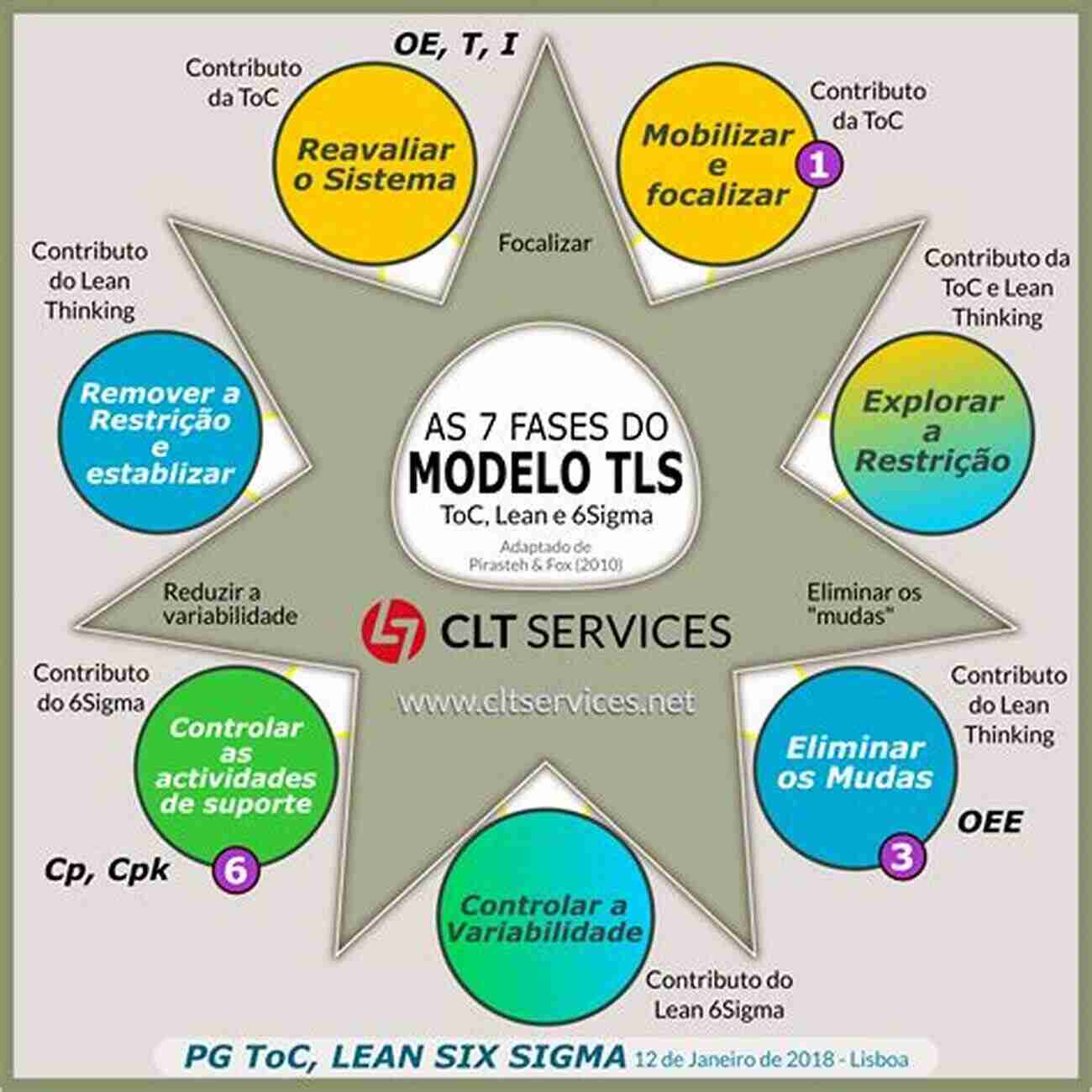

The Ultimate Guide to Theory Of Constraints, Lean, and Six Sigma Improvement Methodology

The Theory of Constraints (TOC),Lean, and Six Sigma are three highly acclaimed improvement methodologies widely used in various industries to enhance productivity, reduce waste, and optimize business processes. In this comprehensive guide, we will delve into the principles, benefits, and applications of each methodology, as well as explore how they can be effectively combined to drive exceptional operational performance.

Theory of Constraints (TOC)

The Theory of Constraints, developed by Eliyahu M. Goldratt, is a management philosophy that focuses on identifying and eliminating the bottlenecks hindering organizational performance. The theory argues that every organization has at least one constraint that limits its ability to achieve its goals. By systematically identifying and resolving these constraints, businesses can optimize their operations and achieve significant improvements in efficiency and profitability.

Key Principles:

4.5 out of 5

| Language | : | English |

| File size | : | 22470 KB |

| Print length | : | 306 pages |

| Screen Reader | : | Supported |

- Identify the constraint: The first step in applying the Theory of Constraints is to identify the bottleneck or constraint that limits the overall performance of the system.

- Exploit the constraint: Once the constraint is identified, efforts should be focused on maximizing its utilization and throughput.

- Subordinate everything else to the constraint: Other processes and activities should be aligned to support and ensure the smooth flow through the constraint.

- Elevate the constraint: If the constraint cannot be fully exploited, additional resources or improvements should be made to elevate its capacity.

- Repeat the process: As constraints are resolved, new ones may arise, and the process of continuous improvement should be repeated.

Lean

Lean, famously pioneered by Toyota, is a systematic approach for eliminating waste and creating value in processes. It aims to maximize customer value while minimizing resource expenditure and activities that do not add value. Lean is centered around five core principles:

- Value: Identify what customers perceive as valuable and focus on delivering that value to them.

- Value Stream: Analyze the end-to-end process and eliminate any activities that do not contribute to value creation.

- Flow: Ensure smooth and uninterrupted flow of products or services through the value stream.

- Pull: Allow customers to pull products or services as they need them, minimizing excess inventory and overproduction.

- Perfection: Strive for continuous improvement and perfection in all aspects of the process.

Six Sigma

Six Sigma is a data-driven methodology aimed at reducing defects, errors, and variations in processes. Originating from Motorola, the methodology utilizes statistical analysis and problem-solving techniques to improve quality and achieve operational excellence. The Six Sigma approach follows a structured five-step process known as DMAIC:

- Define: Clearly define and scope the problem or opportunity for improvement.

- Measure: Measure the current process performance and collect relevant data.

- Analyze: Analyze the data to identify the root cause(s) of the problem or variation.

- Improve: Implement solutions and improvements to address the root cause(s).

- Control: Establish controls to sustain the improvements and ensure the process remains stable.

Combining TOC, Lean, and Six Sigma

While each methodology offers unique benefits, their combination can provide a comprehensive approach to process improvement. By leveraging Lean principles to eliminate waste and improve flow, Six Sigma methodologies to reduce defects and variations, and the Theory of Constraints to identify and prioritize constraints, organizations can achieve remarkable results.

However, successful integration requires a deep understanding of each methodology, as well as effective change management and organizational buy-in. It is crucial to carefully assess the needs and goals of your organization, as well as the specific challenges faced, to determine the most appropriate way to integrate these methodologies.

Benefits of TOC, Lean, and Six Sigma Integration

- Enhanced efficiency: By identifying constraints, eliminating waste, and reducing variations, organizations can streamline their processes and significantly improve overall efficiency.

- Improved quality: Six Sigma principles help organizations reduce defects and errors, ensuring higher quality products and services.

- Cost reduction: Through waste elimination and process optimization, organizations can reduce costs and increase profitability.

- Increased speed: By eliminating non-value adding activities and optimizing flow, organizations can achieve shorter cycle times and faster delivery.

- Better customer satisfaction: The integration of these methodologies leads to improved quality, faster response times, and greater value, resulting in higher customer satisfaction.

Theory of Constraints, Lean, and Six Sigma are powerful improvement methodologies that have revolutionized the way organizations approach operational challenges. When combined effectively, these methodologies can drive significant improvements in efficiency, quality, and customer satisfaction. However, it is important to remember that successful implementation requires careful planning, strong leadership, and a commitment to continuous improvement.

Whether you choose to adopt one methodology or integrate all three, the key is to understand the unique principles and tools they offer and tailor them to your organization's specific needs. Embracing these methodologies can lead to sustainable success and forge a path towards operational excellence.

4.5 out of 5

| Language | : | English |

| File size | : | 22470 KB |

| Print length | : | 306 pages |

| Screen Reader | : | Supported |

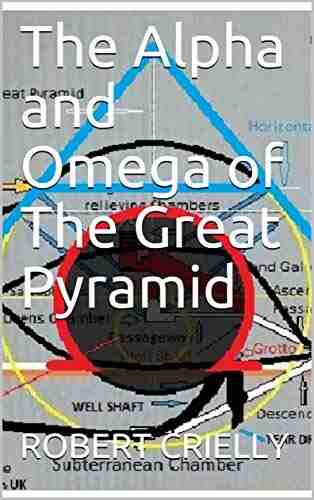

Many leaders and managers have led improvement initiatives in a variety of different industry sectors. Most believe that when they begin these efforts, they already have the tools they need in their improvement "backpack." Using these tools, they make substantial improvements to processes in a wide array of industry segments. As time passes, however, most realize that there is a missing link in their arsenal of tools for improvement. The author of this book faced this same predicament and he discovered what the missing link was in his improvement tool kit: Theory of Constraints (TOC). Once he learned the details of TOC, his ability to make major improvements jettisoned upward to levels he had not seen before. TOC is the common denominator in all the case studies presented in this book.

This book opens with a chapter on what Theory of Constraints is and why it works so well in improvement efforts. The second and third chapters cover the important points related to Lean Manufacturing and Six Sigma as well as key points related to variability. Chapter 4 demonstrates how to effectively combine these three components to achieve maximum improvement and the corresponding enhancement to your company’s profitability. The remainder of this book is composed of true case studies from different industry segments, using this integrated improvement methodology.

Essentially, this book lays the foundation for what most practitioners are just beginning to understand—this integrated improvement methodology is superior to the three components used in isolation from each other. This book presents a step-by-step method of how to combine the Theory of Constraints, Lean, and Six Sigma, and then demonstrates its effectiveness in a very diverse array of industries.

Reed Mitchell

Reed MitchellTango For Chromatic Harmonica Dave Brown: Unleashing the...

The hauntingly beautiful sound of the...

Patrick Rothfuss

Patrick RothfussHow To Tie The 20 Knots You Need To Know

Knot-tying is an essential...

Vince Hayes

Vince HayesThe Politics Experiences and Legacies of War in the US,...

War has always had a profound impact...

Leo Mitchell

Leo MitchellThe Psychedelic History Of Mormonism Magic And Drugs

Throughout history, the connections between...

Michael Simmons

Michael SimmonsThe Practical Japan Travel Guide: All You Need To Know...

Japan, known for its unique...

Deion Simmons

Deion SimmonsDigital Subtraction Flash Cards in Color: Shuffled Twice...

Mathematics is an essential...

Emanuel Bell

Emanuel BellUnveiling the Enigma: Explore the Fascinating World of...

Hello, dear readers! Today, we have a...

Darren Nelson

Darren NelsonHow To Handle Your Parents - A Comprehensive Guide

Are you having trouble dealing with your...

Jimmy Butler

Jimmy ButlerThe Loopy Coop Hens Letting Go: A Tale of Friendship and...

Once upon a time, in a peaceful...

Charles Dickens

Charles DickensGreen Are My Mountains: An Autobiography That Will Leave...

Are you ready to embark on an...

Drew Bell

Drew BellRogue Trainer Secrets To Transforming The Body...

In this fast-paced...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Richard SimmonsThe Sceptical Chymist Or Chymico Physical Doubts Paradoxes Touching The -...

Richard SimmonsThe Sceptical Chymist Or Chymico Physical Doubts Paradoxes Touching The -... Everett BellFollow ·9.9k

Everett BellFollow ·9.9k Shannon SimmonsFollow ·19.7k

Shannon SimmonsFollow ·19.7k Travis FosterFollow ·19.8k

Travis FosterFollow ·19.8k Bryan GrayFollow ·15.3k

Bryan GrayFollow ·15.3k Joshua ReedFollow ·17.2k

Joshua ReedFollow ·17.2k Hudson HayesFollow ·14k

Hudson HayesFollow ·14k Benjamin StoneFollow ·6.6k

Benjamin StoneFollow ·6.6k John Dos PassosFollow ·13.4k

John Dos PassosFollow ·13.4k