Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Manufacturing In Transition And Business Studies: A Complete Guide To Staying Ahead

Manufacturing has come a long way since the Industrial Revolution. Today, the sector is not just about production, but also about innovation, digitization, and sustainability. To navigate this ever-changing landscape, it is crucial for businesses to stay informed and adapt accordingly. In this comprehensive guide, we will explore the trends shaping manufacturing, the role of technology, and the pivotal link between manufacturing and business studies.

Trends in Manufacturing

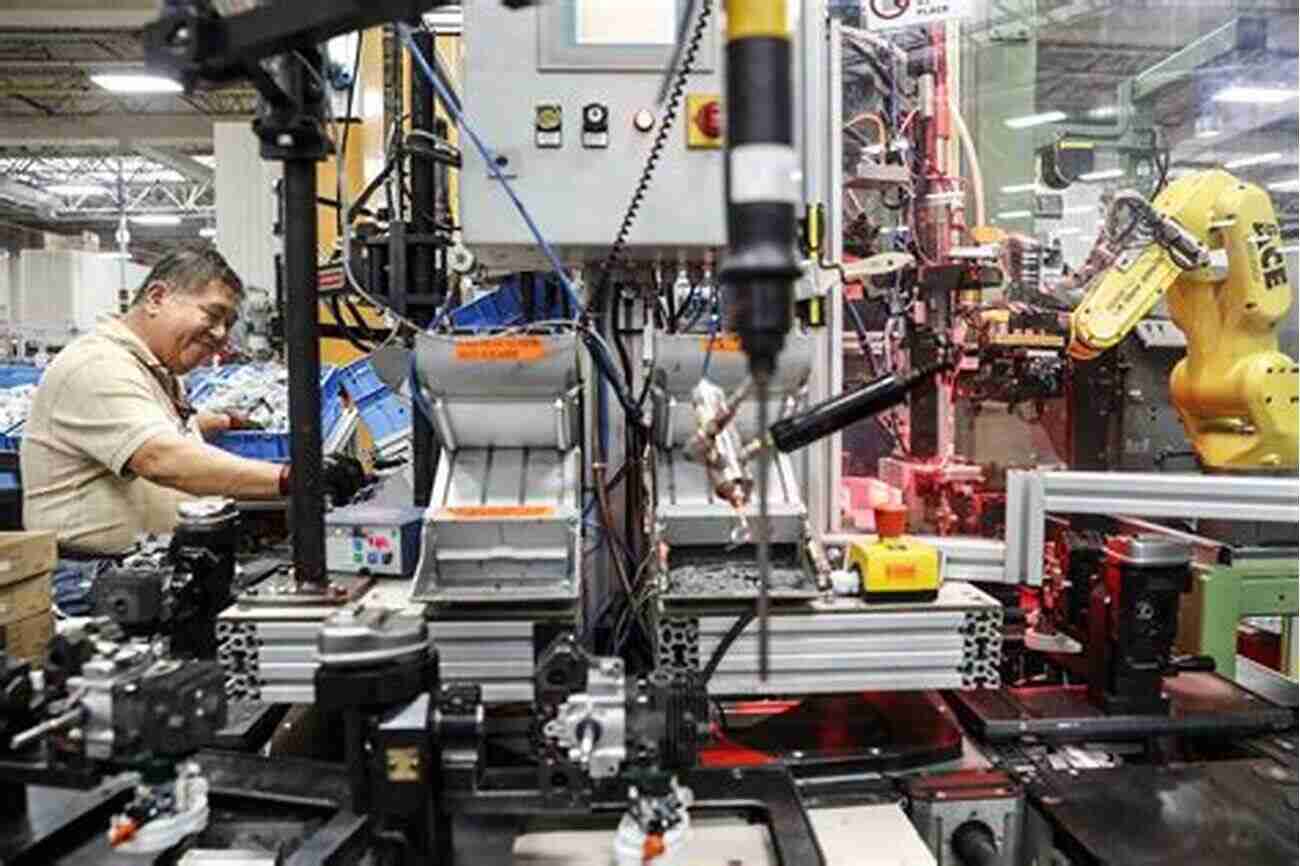

The manufacturing industry has witnessed several significant shifts over the past decade. From embracing automation and robotics to adopting sustainable practices, businesses are constantly evolving to meet changing consumer demands. Let's delve deeper into some key trends:

1. Automation and Robotics

Automation and robotics have revolutionized the manufacturing industry. With the rise of smart machines and artificial intelligence, tasks that were once performed manually are now automated for improved speed, accuracy, and efficiency. This transition has allowed businesses to streamline production processes, reduce costs, and enhance overall productivity.

5 out of 5

| Language | : | English |

| File size | : | 8332 KB |

| Text-to-Speech | : | Enabled |

| Enhanced typesetting | : | Enabled |

| Print length | : | 81 pages |

| Lending | : | Enabled |

| Screen Reader | : | Supported |

| Paperback | : | 288 pages |

| Item Weight | : | 13.9 ounces |

| Dimensions | : | 6.14 x 0.64 x 9.21 inches |

Additionally, robots are not limited to repetitive tasks anymore. They are now capable of complex operations, enabling manufacturers to take on more challenging projects and increase customization. By leveraging automation, companies can maintain a competitive edge in today's fast-paced market.

2. Sustainable Manufacturing

As sustainability becomes a global priority, manufacturing has taken center stage in adopting environmentally friendly practices. From reducing carbon emissions to optimizing energy usage, businesses are striving to minimize their ecological footprint. This shift towards sustainable manufacturing not only benefits the environment but also attracts eco-conscious consumers. By incorporating renewable energy sources, recycling, and responsible waste management, manufacturers can bolster their image and appeal to a wider customer base.

3. Additive Manufacturing and 3D Printing

Another transformative trend in manufacturing is additive manufacturing, commonly known as 3D printing. This technology allows businesses to create three-dimensional objects by layering materials, eliminating the need for traditional manufacturing processes. 3D printing offers several advantages, including reduced waste, faster production times, and enhanced customization capabilities. This technology opens up new possibilities for industries ranging from aerospace to healthcare, revolutionizing supply chains and product development.

The Role of Technology

In an era of rapid technological advancements, businesses need to stay ahead of the curve and leverage technology to their advantage. The manufacturing sector is no exception. Let's explore the role of technology in shaping modern manufacturing:

1. Internet of Things (IoT)

The Internet of Things (IoT) is reshaping manufacturing by connecting devices, sensors, and machinery, enabling seamless communication and data exchange. This connectivity allows manufacturers to monitor production lines in real-time, identify bottlenecks, and improve overall efficiency. IoT also provides valuable insights into equipment maintenance, reducing downtime and increasing productivity. By harnessing the power of IoT, businesses can achieve higher levels of automation, optimize resource utilization, and enhance decision-making processes.

2. Big Data and Analytics

With the exponential growth of data, businesses need sophisticated analytics tools to extract actionable insights. In manufacturing, big data analytics enables predictive maintenance, quality control, and supply chain optimization. By analyzing vast amounts of data generated across production processes, businesses can detect patterns, identify inefficiencies, and make data-driven decisions. This information empowers manufacturers to minimize risks, improve productivity, and deliver products that align with customer preferences.

3. Cloud Computing

Cloud computing has revolutionized data storage, collaboration, and accessibility across various industries, including manufacturing. By leveraging the cloud, manufacturers can seamlessly share data and resources, enhance collaboration between teams, and ensure real-time updates across different locations. Cloud-based systems also provide scalability and flexibility, allowing businesses to adapt quickly to market demands. This technology reduces infrastructure costs, enhances data security, and improves overall operational efficiency.

The Connection between Manufacturing and Business Studies

Manufacturing and business studies are intricately linked, with each discipline complementing the other. Let's explore how a solid understanding of business studies can benefit manufacturing:

1. Strategic Planning

A key component of business studies is strategic planning. By understanding market trends, consumer behavior, and competitive landscapes, manufacturers can develop effective strategies to stay ahead in the industry. Business studies provide valuable insights into marketing strategies, financial planning, and supply chain management. Armed with this knowledge, manufacturers can make informed decisions, mitigate risks, and seize opportunities.

2. Quality Management and Continuous Improvement

Quality management and continuous improvement are essential aspects of manufacturing. Business studies equip manufacturers with the tools to analyze processes, identify bottlenecks, and implement quality control measures. By incorporating frameworks such as Six Sigma or Lean Manufacturing, businesses can reduce defects, increase customer satisfaction, and improve overall efficiency. Business studies also emphasize the importance of Kaizen, a philosophy centered around continuous improvement, ensuring that manufacturing processes evolve and optimize over time.

3. Supply Chain Management

Efficient supply chain management is crucial for successful manufacturing operations. Business studies provide manufacturers with a holistic understanding of supply chain dynamics, including sourcing, procurement, logistics, and inventory management. By optimizing these processes, manufacturers can reduce costs, enhance agility, and meet customer demands effectively. With in-depth knowledge of supply chain management, businesses can establish strategic partnerships, streamline operations, and minimize disruptions across the value chain.

5 out of 5

| Language | : | English |

| File size | : | 8332 KB |

| Text-to-Speech | : | Enabled |

| Enhanced typesetting | : | Enabled |

| Print length | : | 81 pages |

| Lending | : | Enabled |

| Screen Reader | : | Supported |

| Paperback | : | 288 pages |

| Item Weight | : | 13.9 ounces |

| Dimensions | : | 6.14 x 0.64 x 9.21 inches |

The future of British manufacturing is of immense importance and topicality. As we slide towards a service sector economy based on finance and tourism, it is worth reflecting on whether this is the most appropriate or inevitable scenario.

Manufacturing in Transition makes a genuinely interdisciplinary contribution to the debate over the UK's strategy for industrial renewal. Aimed primarily at business, economics and industrial relations students, it looks at the current state of British manufacturing sector within the global economy and asks whether manufacturing matters in the twenty first century.

The books explores key issues such as:

the chances of renewal

* developments in the management and organisation of operations and supply chains

* the differences made by Japanese methods

This is a timely assessment of the UK's industrial development and makes a major contribution to debates over the industrial strategy and the position of manufacturing within industrialized economies.

Reed Mitchell

Reed MitchellTango For Chromatic Harmonica Dave Brown: Unleashing the...

The hauntingly beautiful sound of the...

Patrick Rothfuss

Patrick RothfussHow To Tie The 20 Knots You Need To Know

Knot-tying is an essential...

Vince Hayes

Vince HayesThe Politics Experiences and Legacies of War in the US,...

War has always had a profound impact...

Leo Mitchell

Leo MitchellThe Psychedelic History Of Mormonism Magic And Drugs

Throughout history, the connections between...

Michael Simmons

Michael SimmonsThe Practical Japan Travel Guide: All You Need To Know...

Japan, known for its unique...

Deion Simmons

Deion SimmonsDigital Subtraction Flash Cards in Color: Shuffled Twice...

Mathematics is an essential...

Emanuel Bell

Emanuel BellUnveiling the Enigma: Explore the Fascinating World of...

Hello, dear readers! Today, we have a...

Darren Nelson

Darren NelsonHow To Handle Your Parents - A Comprehensive Guide

Are you having trouble dealing with your...

Jimmy Butler

Jimmy ButlerThe Loopy Coop Hens Letting Go: A Tale of Friendship and...

Once upon a time, in a peaceful...

Charles Dickens

Charles DickensGreen Are My Mountains: An Autobiography That Will Leave...

Are you ready to embark on an...

Drew Bell

Drew BellRogue Trainer Secrets To Transforming The Body...

In this fast-paced...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Miguel de CervantesPacifism: Embracing the Philosophy of Nonviolence for a Peaceful World

Miguel de CervantesPacifism: Embracing the Philosophy of Nonviolence for a Peaceful World

Christian CarterModern Inline Muzzleloader Guide To Loading Shooting Cleaning For Accuracy

Christian CarterModern Inline Muzzleloader Guide To Loading Shooting Cleaning For Accuracy Leon FosterFollow ·10.5k

Leon FosterFollow ·10.5k Giovanni MitchellFollow ·4.3k

Giovanni MitchellFollow ·4.3k Billy FosterFollow ·2.7k

Billy FosterFollow ·2.7k Adrian WardFollow ·6.8k

Adrian WardFollow ·6.8k D'Angelo CarterFollow ·19.2k

D'Angelo CarterFollow ·19.2k Wesley ReedFollow ·12k

Wesley ReedFollow ·12k Eddie PowellFollow ·5.9k

Eddie PowellFollow ·5.9k Fernando BellFollow ·3.9k

Fernando BellFollow ·3.9k